Unleashing the Power of CNC Machining in Modern Metal Fabrication

In the realm of metal fabrication, the advent of Computer Numerical Control (CNC) machining has revolutionized manufacturing processes, elevating precision, scalability, and efficiency to unprecedented levels. For metal fabricators seeking to optimize their production capabilities and deliver superior quality products, embracing CNC machining is no longer optional—it's imperative.

What is CNC Machining and Why It Matters in Metal Fabrication

CNC machining refers to the automated control of machine tools through computer programming. This technology allows for meticulous, highly accurate, and repeatable cutting, milling, drilling, and shaping of metal components. Unlike traditional manual machining, CNC systems leverage sophisticated algorithms and software to execute complex operations with minimal human intervention, reducing errors and waste.

For metal fabricators, integrating cnc machining into their workflows means achieving closer tolerances, intricate geometries, and faster turnaround times. As industries demand more complex parts—from aerospace components to automotive frames—the importance of CNC technology continues to grow exponentially.

The Advantages of CNC Machining for Metal Fabricators

- Exceptional Precision and Accuracy: CNC machines can produce parts with tolerances as tight as ±0.001 inches, ensuring that each piece meets strict specifications without manual adjustments.

- High Repeatability and Consistency: Once a design is programmed, CNC systems can reproduce identical parts hundreds or thousands of times with minimal variation—ideal for mass production.

- Enhanced Complex Geometries: CNC technology allows for the creation of highly intricate and precise shapes that are impossible to achieve with traditional methods.

- Reduced Lead Times: Automated processes streamline manufacturing, enabling faster project completion and quicker response to market demands.

- Cost Efficiency: Although initial setup costs may be higher, long-term savings come from reduced material waste, lower labor costs, and minimized errors.

- Versatility Across Materials: CNC machining is compatible with a wide range of metals including aluminum, steel, titanium, brass, and copper, making it adaptable to diverse project requirements.

The Role of CNC Machining in Modern Metal Fabricators' Operations

For companies specializing in metal fabricators, cnc machining serves as a core technology that enhances every stage of production—from initial design to finishing. It enables the creation of complex assemblies, custom parts, and prototypes with unmatched precision and speed.

Moreover, CNC machining facilitates seamless integration with other manufacturing processes such as welding, metal forming, and surface treatments, creating a comprehensive, efficient workflow that boosts productivity and product quality.

Key Applications of CNC Machining in Metal Fabrication Industries

- Aerospace: Precision-cut turbine blades, structural components, and intricate aerodynamic parts.

- Automotive: Manufacturing of engine blocks, transmission parts, and custom chassis pieces with tight tolerances.

- Medical Devices: Producing complex surgical instruments, implants, and prosthetics with biocompatible metals.

- Industrial Machinery: Fabricating durable, detailed components for heavy equipment and industrial automation.

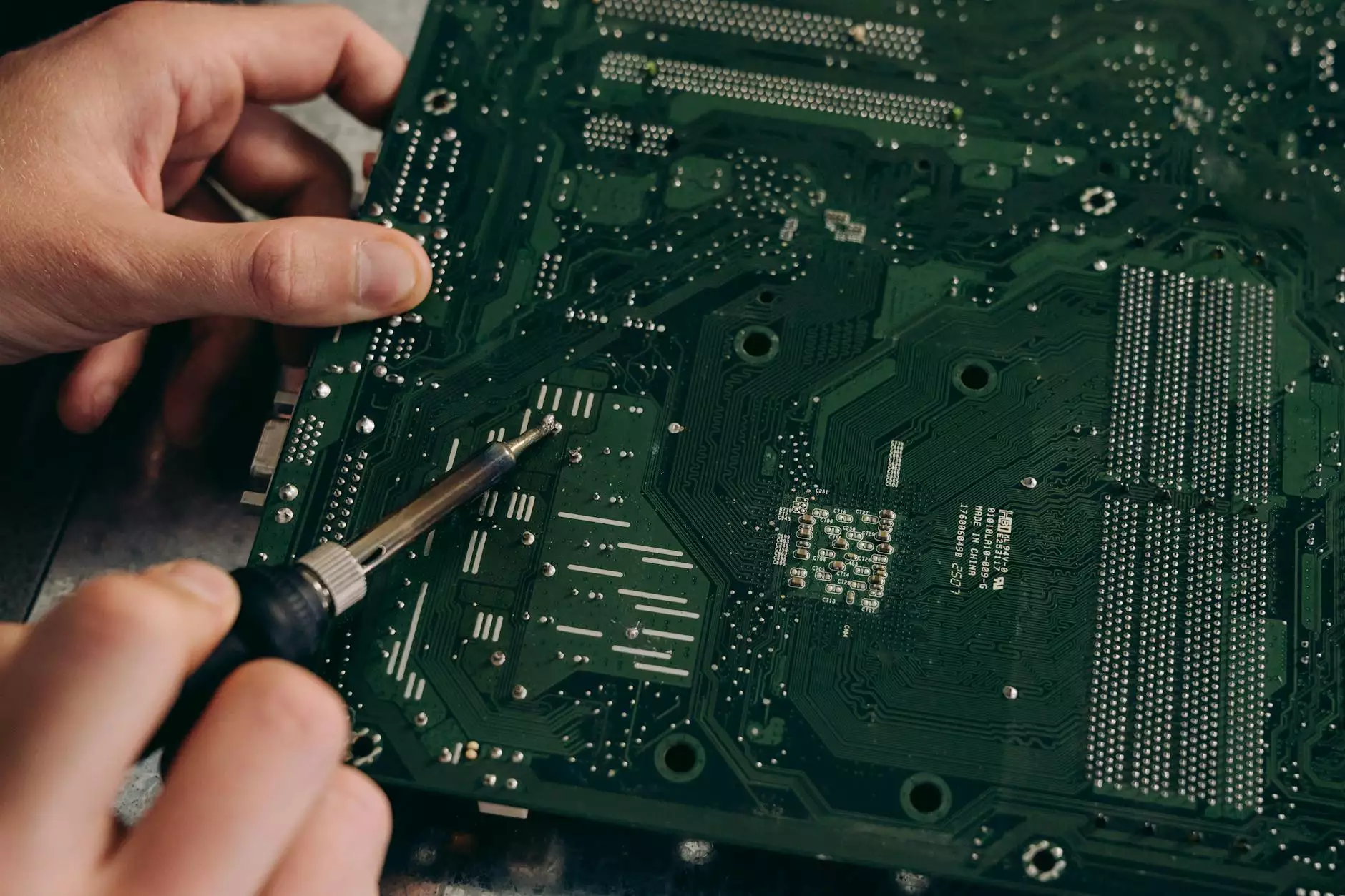

- Electrical and Electronics: Crafting precise metal casings, connectors, and heat sinks.

Choosing the Right CNC Equipment for Metal Fabrication

Selecting suitable cnc machining equipment is crucial to maximize efficiency and quality. Key factors include:

- Machine Type: From CNC mills and lathes to multi-axis machines, the choice depends on part complexity and production volume.

- Material Compatibility: Ensuring the machine can handle specific metals, especially high-strength or heat-sensitive materials.

- Precision Capabilities: Evaluating tolerances and surface finish options to meet project specifications.

- Automation and Control Features: Advanced software integration, automation tools, and ease of programming enhance productivity.

Partnering with experienced suppliers like deepmould.net can provide access to state-of-the-art CNC equipment and expert guidance tailored for metal fabricators.

Integrating CNC Machining with Digital Design and Manufacturing

The integration of CNC machining with digital design tools—such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing)—transforms traditional manufacturing into a highly sophisticated process. With this synergy:

- Design to Production Loop: Concepts are instantly converted into machine code, reducing lead times from design to production.

- Prototyping Enhancements: Rapid prototypes can be produced for testing, validation, and iterative improvements.

- Quality Control: Digital monitoring and measurement systems ensure products meet exact specifications, with precise adjustments made in real-time.

This digital transformation supports metal fabricators in maintaining competitive advantages through innovation and agility.

Future Trends in CNC Machining for Metal Fabrication

The future of cnc machining in metal fabrication is driven by continual technological advancements, including:

- Enhanced Automation: Increased use of robotics and AI for autonomous operation, setup, and maintenance.

- Industry 4.0 Integration: Smart factories with interconnected machines, real-time data analytics, and predictive maintenance.

- Hybrid Machining Processes: Combining additive manufacturing with CNC to create complex, multi-material components.

- Sustainable Manufacturing: Innovations aimed at reducing material waste, energy consumption, and environmental impact.

Adopting these trends will empower metal fabricators to stay ahead in a highly competitive global marketplace.

Partnering with Experts in CNC Machining for Scientific and Commercial Success

To leverage the full potential of cnc machining and ensure top-tier results, partnering with experienced, reliable providers is essential. DeepMould specializes in supporting metal fabricators with cutting-edge CNC solutions, expert technical support, and comprehensive manufacturing services.

With their expertise, your business can achieve:

- Enhanced Product Quality: Precision-engineered components that meet or exceed industry standards.

- Operational Efficiency: streamlined workflows reducing production costs and lead times.

- Innovative Capabilities: Access to the latest CNC technologies for complex, high-value projects.

- Scalability: Flexible solutions that grow with your business needs.

Partnering with industry leaders will help your metal fabrication enterprise thrive and lead in quality and innovation.

Conclusion: Embracing CNC Machining for a Bright Future in Metal Fabrication

In summary, cnc machining is not just a manufacturing process—it's a strategic asset that can dramatically enhance the capabilities of any metal fabricator. Through unmatched precision, efficiency, and flexibility, CNC technology empowers businesses to meet the evolving demands of industries worldwide.

As digital transformation continues to accelerate, integrating advanced CNC systems with the latest design and automation tools will become increasingly vital for maintaining competitive excellence.

Furthermore, collaborating with dedicated experts like DeepMould can unlock new opportunities for innovation and growth, helping your enterprise lead with confidence in the modern era of metal fabrication.

Elevate your manufacturing process today—embrace the power of cnc machining and build a resilient, forward-thinking metal fabrication business.